Introduction

In the context of increasing global climate change and energy security, there is an urgent need to transition to sustainable energy sources. The carbon emissions and dependence on conventional petroleum fuels have become a major issue for us. Among them, the current automotive system architecture, which is dominated by the internal combustion engine, has been greatly challenged. While some are cheering for the full-scale electrification of the automotive industry, an emerging technology solution is receiving increasing attention and interest, E-Fuels (electronic fuels). This article will introduce the concept of E-Fuels, the manufacturing process and their application in the transportation and aviation industries, while exploring their advantages, challenges and prospects.

What are E-Fuels?

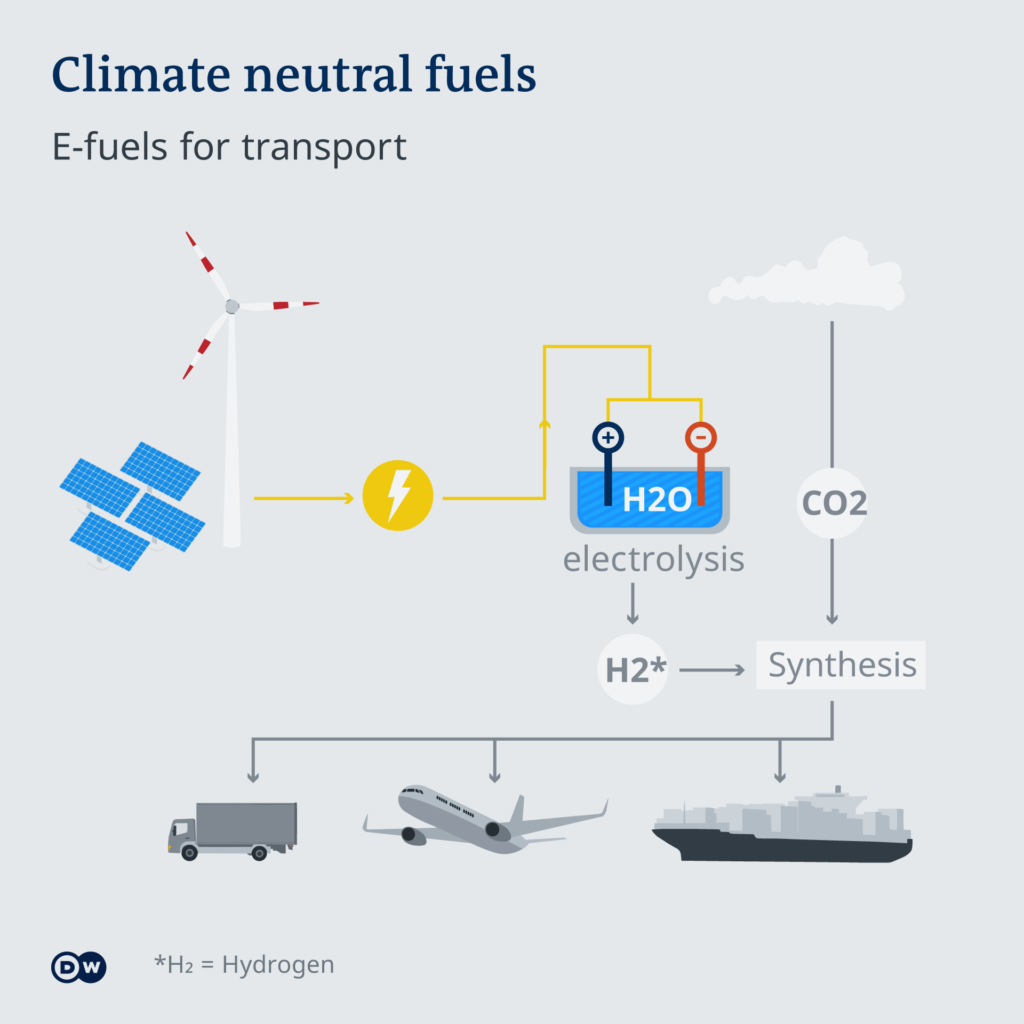

E-Fuels are a class of synthetic fuels that are manufactured using renewable energy sources, such as solar and wind, to produce fuel through reactions such as hydrogen production from electrolysis of water and the capture and utilization of carbon dioxide. These fuels are similar to conventional petroleum fuels and can be used in existing fuel infrastructures while being able to reduce carbon emissions.

Advantages of E-Fuels:

First, the manufacturing process of E-Fuels utilizes renewable energy, which is one of its greatest advantages. Renewable energy sources such as solar, wind and water are abundant and lasting sources of energy on the planet. By using these renewable energy sources to produce E-Fuels, we can reduce our dependence on limited petroleum resources and not further exacerbate environmental problems. This creates a sustainable energy future for us.

Second, the use of E-Fuels can significantly reduce carbon emissions. The combustion process of conventional fuels releases large amounts of carbon dioxide and other greenhouse gases, reinforcing the global warming trend. However, E-Fuels capture and utilize carbon dioxide in the manufacturing process, making it a recycled and renewable energy source. By using E-Fuels to replace conventional fuels, we can reduce carbon emissions in transportation and industry, making an important contribution to combating climate change.

Third, E-Fuels are compatible with conventional petroleum fuels and can be used in existing fuel infrastructures, which is another important advantage. No major infrastructure modifications are required, and vehicles and machinery can use E-Fuels directly without expensive retrofits or replacements. This compatibility means that we can achieve a smooth transition and gradually replace conventional fuels with sustainable E-Fuels, making efficient use of existing infrastructure and services.

In addition, E-Fuels offer high energy density and storage stability, making them a reliable energy option. Taking CO2 hydrogenation to methanol as an example, the energy density of methanol is about 6400 Wh/kg, conventional gasoline is about 12,200 Wh/kg [2], and the latest CTP3.0 Qilin battery from CATL is about 255 Wh/kg [3]. Compared with current battery technologies, E-Fuels can provide longer driving range and faster refueling times to meet the needs of the transportation and aviation industries. This energy density and storage stability advantage makes E-Fuels an important solution for achieving sustainable mobility and industrialization.

Manufacturing process of E-Fuels:

The manufacturing process of E-Fuels includes electrolytic water hydrogen production, CO2 capture and utilization, and fuel synthesis and processing. Electrolytic water to hydrogen is a process that breaks down water into hydrogen and oxygen, producing high purity hydrogen by using renewable energy to drive the electrolysis reaction. Then, carbon dioxide can be converted into syngas by capturing the carbon dioxide produced in the industrial process and reacting it with the hydrogen produced in the manufacturing process. Finally, the syngas is used as a feedstock to form the final liquid hydrocarbon fuel product through a Fischer-Tropsch process.

Application areas of E-Fuels:

The application area of E-Fuels is mainly focused on transportation. E-Fuels can be used as an alternative fuel for cars, trucks and ships, reducing exhaust emissions and improving air quality. In addition, E-Fuels can be used in public transportation and freight fleets to further reduce the carbon footprint. Relevant stakeholders have formed an industry group, the eFuel Alliance, which includes large German automotive component suppliers such as Bosch, ZF and others, as well as oil and gas giants such as ExxonMobil, Repsol and others. Porsche has invested $75 million in the Chilean fuel company HIF Global LLC. In the future HIF will expand the production of E-Fuels to achieve a larger scale of supply.

In the aviation industry, E-Fuels can be used as a sustainable alternative to aviation fuels, reducing the carbon footprint of the aviation industry. The global aviation industry consumes about 7.95 million barrels of kerosene per day [4]. Although the current production of E-Fuels is far from meeting the demand, E-Fuels can be blended into existing fuels. The European Commission has proposed a mandatory 5% blend of sustainable aviation fuels (SAF) to match existing aviation fuels by 2030. From 2030, the plan is for E-Fuels to account for 0.7% of total aviation fuel use to 28% by 2050 [5]. Siemens Energy is actively promoting the testing and promotion of flights using E-Fuels to reduce the aviation industry’s dependence on fossil fuels [6].

Challenges and prospects:

E-Fuels also face a number of challenges. First, the cost of manufacturing E-Fuels is currently high because the cost of renewable energy is still high and production is limited. Hydrogen production from renewable energy sources using electrolytic water is an important part of achieving 100% zero greenhouse gas emissions. The main sources of hydrogen currently are 1) steam reforming: hydrogen is produced by the reaction of fossil fuels such as oil and natural gas with raining water vapor at high temperatures; 2) by-product hydrogen: hydrogen is produced as a by-product of coke production from steam coal or caustic soda in steel mills that make coke; and 3) biomass hydrogen: hydrogen is produced by gasifying and reforming biomass energy sources. Renewable energy electrolytic water hydrogen production still requires huge investments to promote cheap and clean green hydrogen to circulate in industry.

In addition, scaling up the production capacity of E-Fuels also requires addressing the technical challenges of large scale CO2 capture and reuse.E-Fuels as a way to reuse CO2 resources, catalyst selection to improve the conversion rate of CO2 and selectivity of target products is a major direction of current research.

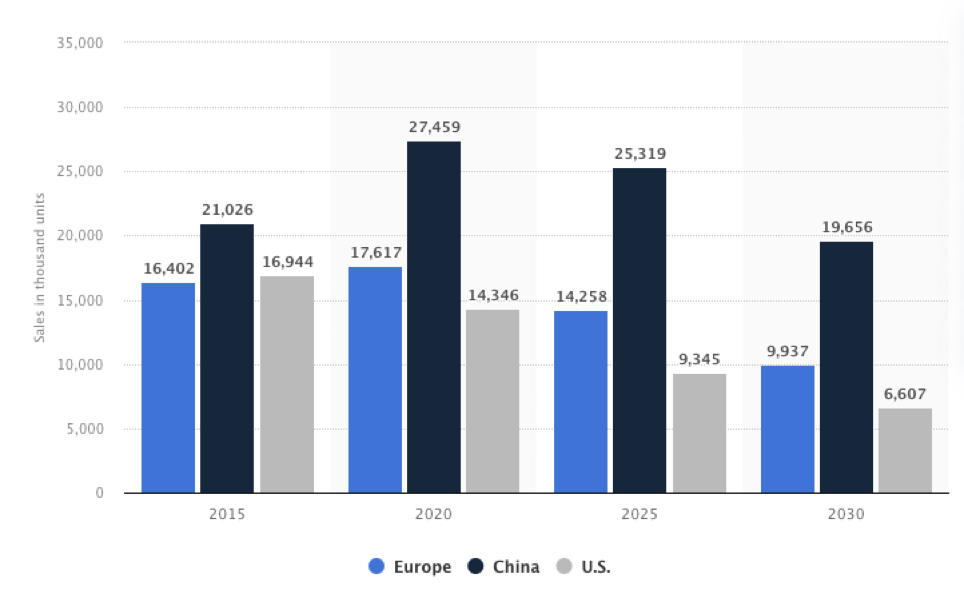

The outlook of E-Fuels is positive. Countries are actively promoting carbon peaking and carbon neutrality. in September 2020, China announced to the world at the United Nations General Assembly the goal of achieving carbon peaking by 2030 and carbon neutrality by 2060. However, it is expected that 36.2 million ICE vehicles will still be sold by 2030, including in China, Europe and the United States. The use of synthetic fuels like E-fuels with near carbon-neutral will contribute significantly to the overall decarbonization goal. in March 2023, the European Union has announced that it will allow automakers to sell cars with E-fuels after 2035.

Conclusion:

E-Fuels have great potential to drive the energy transition as a sustainable energy solution. They can reduce carbon emissions, reduce dependence on limited oil resources, and provide clean energy for transportation and aviation. Despite some challenges, E-Fuels are expected to become an important part of the future energy system as technology advances and policies move forward. As more countries and companies invest and cooperate, production scaling up will allow the cost of E-Fuels to come down further and achieve widespread adoption worldwide.

[1] https://www.dw.com/en/batteries-versus-e-fuels-which-is-better/a-61921402

[2] https://everything2.com/index.pl?node=energy%20density

[3] https://www.catl.com/technologybrand/6468.html

[4] https://www.bp.com.cn/content/dam/bp/country-sites/zh_cn/china/home/reports/statistical-review-of-world-energy/2021/BP_Stats_2021.pdf

[5] https://www.easa.europa.eu/en/light/topics/fit-55-and-refueleu-aviation

[6] https://www.siemens-energy.com/global/en/news/magazine/2022/flying-with-e-fuels.html

[7] https://www.statista.com/statistics/961138/ice-vehicle-sales-selected-world-regions/