The end of oil age is happening very quickly. Major European and Asian countries are racing to phase out gasoline and diesel cars. The U.K said in July that it would ban sales of new internal combust engine cars by 2040. France government also said that it wants to end sales of gas and diesel-powered vehicles by 2040. Norway had planned a clear target that all new passenger cars sold in 2025 should be zero-emission vehicles. Although it still has a great uncertainty that electrical vehicles replace internal combust engine cars by 2040, the tread and idea of EVs which become clearer and more popular.

Dream of $100 /kWh

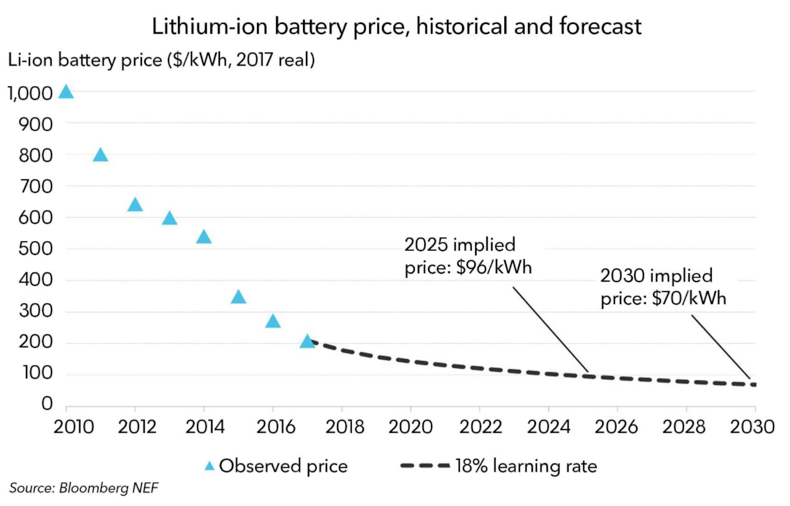

It’s a great challenge and chance for players in energy and automotive industries. The price of EVs would be the key to promoting EVs on a global scale. And the price of electrical vehicles mainly depends on the batteries price which accounts for 20-30% of the material cost in EVs. The battery also will become a key component for product differentiation. Developing affordable batteries with the long driving range is the biggest challenge to increase sales of EVs. Various chemistries are promising, with lithium-ion appearing the dominate type now. Batteries alone are estimated to cost above $8,000 per vehicle. [1] Koji Kobayashi, Toyota Executive Vice President, said EV batteries will cost nearly JPY 1.4 million per car concerning the profitability of EV at the press in Feb. [2] According to the Bloomberg New Energy Finance 2018 report, battery price has fallen by nearly 80% since 2010 and it’s less than $200/Kwh in 2017. It will continue to drop to $70/kWh by 2030. [3]

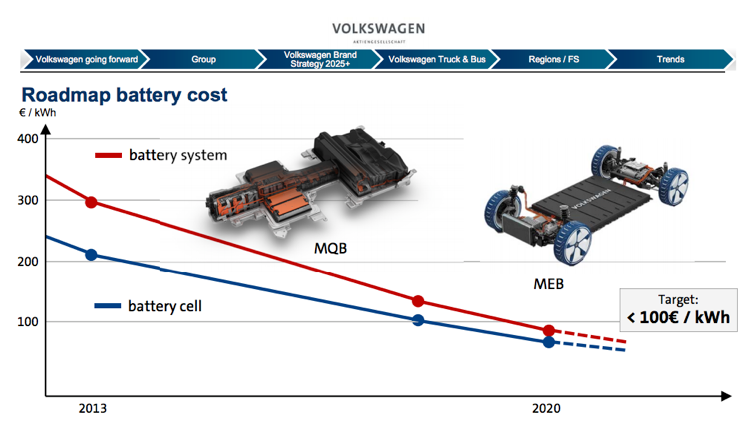

However, Volkswagen has a more aggressive plan. They want to achieve battery price less than $117(€100) /kWh in 2020. This is included in Volkswagen strategy 2025. [4] Volkswagen aim to introduce new toolkit(MEB) [5] to enable cost and concept leadership for EVs. By 2025, they’d like to lunch more than 30 new EVs.

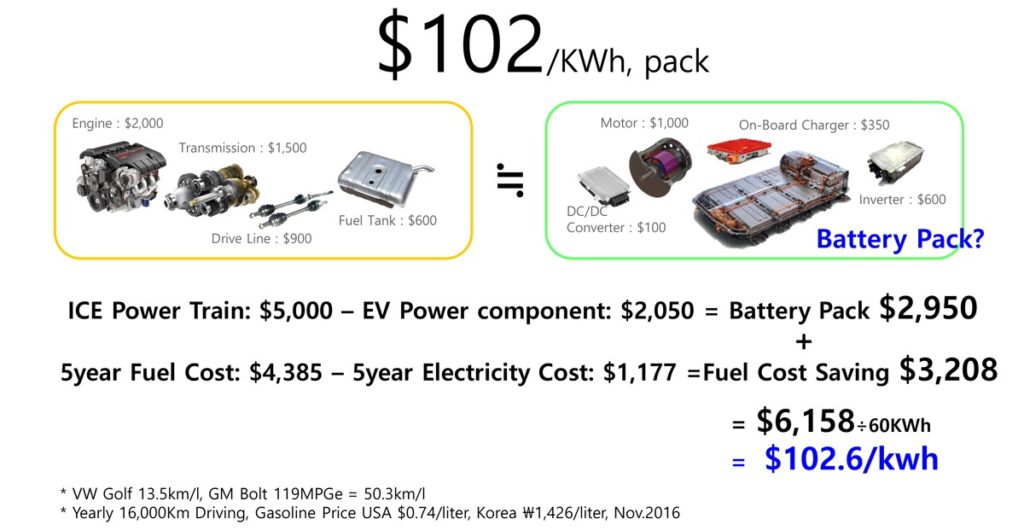

$100/Kwh is a crucial point for EVs because EVs will be cheaper than traditional gasoline when Li-ion batteries cost close to $100/Kwh. SNE Research calculated the cost of a 60kWh battery (approx. 300km) should be close to 102 /Kwh compared with a WM Golf in 5 years.

The key component cost of a VM Golf is $5000:

- Engine: $2000

- Transmission: $1500

- Driveline: $900

- Fuel tank: $600

The key component cost (except battery) of an EV is $2050

- Motor: $1000

- Inventor: $600

- DC/DC Converter: $100

- On-Board Charger: $350

Supposed yearly 16,000 Km and gasoline price is $0.74/L, 5-year fuel cost is $4385 and electricity cost is nearly $1177. Fuel cost saving and battery pack cost are nearly $6158. It requires battery price should be less than $102 /kWh. Furthermore, if we even don’t consider the merit of fuel cost saving, battery price should be around $50 /kWh. We are looking forwarding to battery price will half its price every three years.

Price Going Down

The steep decrease in price is due to the following facts.

- Technology improvements

- Economies of scale

- Competition between the major manufacturers

Technology improvements will indeed help reduce the cost. Tesla Model S(310MJ) has 85kWh which hopes to have 407-438 km driving range according to EPA standard. It contains 7,104 18650-type Li-ion battery cells which have a specific energy density of 250 Wh/kg. Tesla intends to use the new 2170-type cell for the Model 3 cars that come to 300Wh/kg, with 20% more specific energy. Tesla said they achieved this by significantly reducing cobalt content per battery pack while increasing nickel content and still maintaining superior thermal stability. The cathode chemistry used in 2170 is Nickel-Cobalt-Aluminum(NCA). Tesla also said the cobalt content of 2170 cathode is even lower than next-generation cathodes that will be made by other cell producers with a Nickel-Manganese-Cobalt ratio of 8:1:1. [6]

Economies of scale are also showing the power for reducing cost. Tesla and Panasonic invested the Gigafactory 1 in Nevada in 2014, which will have up to 35GWh production by 2020. Some more aggressive plan is shown by Chinese brands. CATL announced to achieve 50 GWh plan by 2020, although it only has 6.8GWh in 2016. CATL said they will achieve battery price under $100/kWh around 2022 since the increase of production capacity. SAMSUNG SDI and LG Chem are also increasing their production capacity.

Competition between the major manufacturers will be intensive. As the stories of LCD panel and the photovoltaic cell, the battery will soon become a red sea. The price competition will become heavily as more player involved in this game.

[1] Battery Manufacturing for Hybrid and Electric Vehicles: Policy Issues

[2] 電池競争、新星は臆さない 中国CATLが台頭

[3] New Energy Outlook 2018

[4] Volkswagen strategy 2025

[5] The E-Mobility Module

[6] Tesla update letter

Thanks for another wonderful post. Where else could anyone get that type of info in such an ideal way of writing? I’ve a presentation next week, and I’m on the look for such info.

Just wish to say your article is as surprising. The clearness for your post is just cool and i could suppose you are a professional in this subject. Well with your permission let me to take hold of your feed to keep updated with approaching post. Thanks 1,000,000 and please carry on the gratifying work.

Thank you! Hope I can write more good ones.

Olly James Kamatu https://i1.apache.org.uk/66.html Paul McCartney Archive Rarities Volume 12